pronto – the digital production control

Powerful. Reliable. Scalable.

In times of digital transformation, production control is the decisive discipline in the value chain of a manufacturing trade. It is much more than only about the automation of production lines.

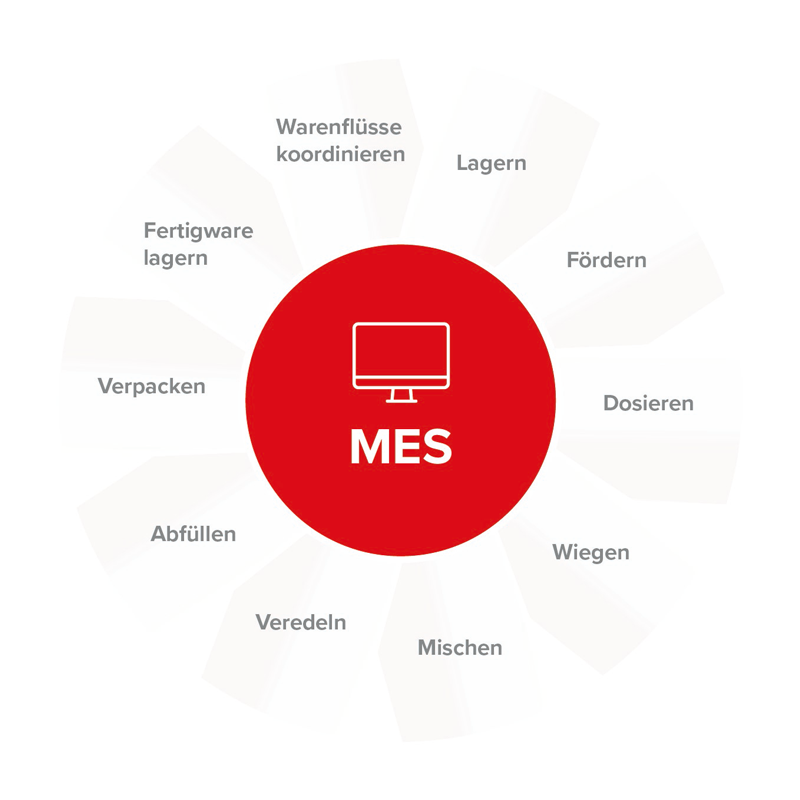

Our manufacturing execution system (MES) pronto couples material management with production technology. Production orders as well as raw material batches – if applicable – are taken from the enterprise resource planning system (ERP) and supplemented with process components, such as machine parameters. pronto interlinks machines and production lines and combines a powerful process visualisation system for operation and monitoring (SCADA) with a system for controlling the process and production management level (MES). On the MES side, it focuses on the control and management of batch-oriented processes and is also optimised for weighing tasks.

By fulfilling all the requirements of the process and production management levels, pronto forms a homogeneous overall system not only for control, but especially for the complete documentation of the production process. All processes carried out in production are controlled by pronto. This applies to automated processes as well as to the operator guidance during manual operations. A comprehensive process documentation is ensured, of course also regarding the material management. This comprehensively provides for reverse batch tracing and tracking of incoming raw material batches.