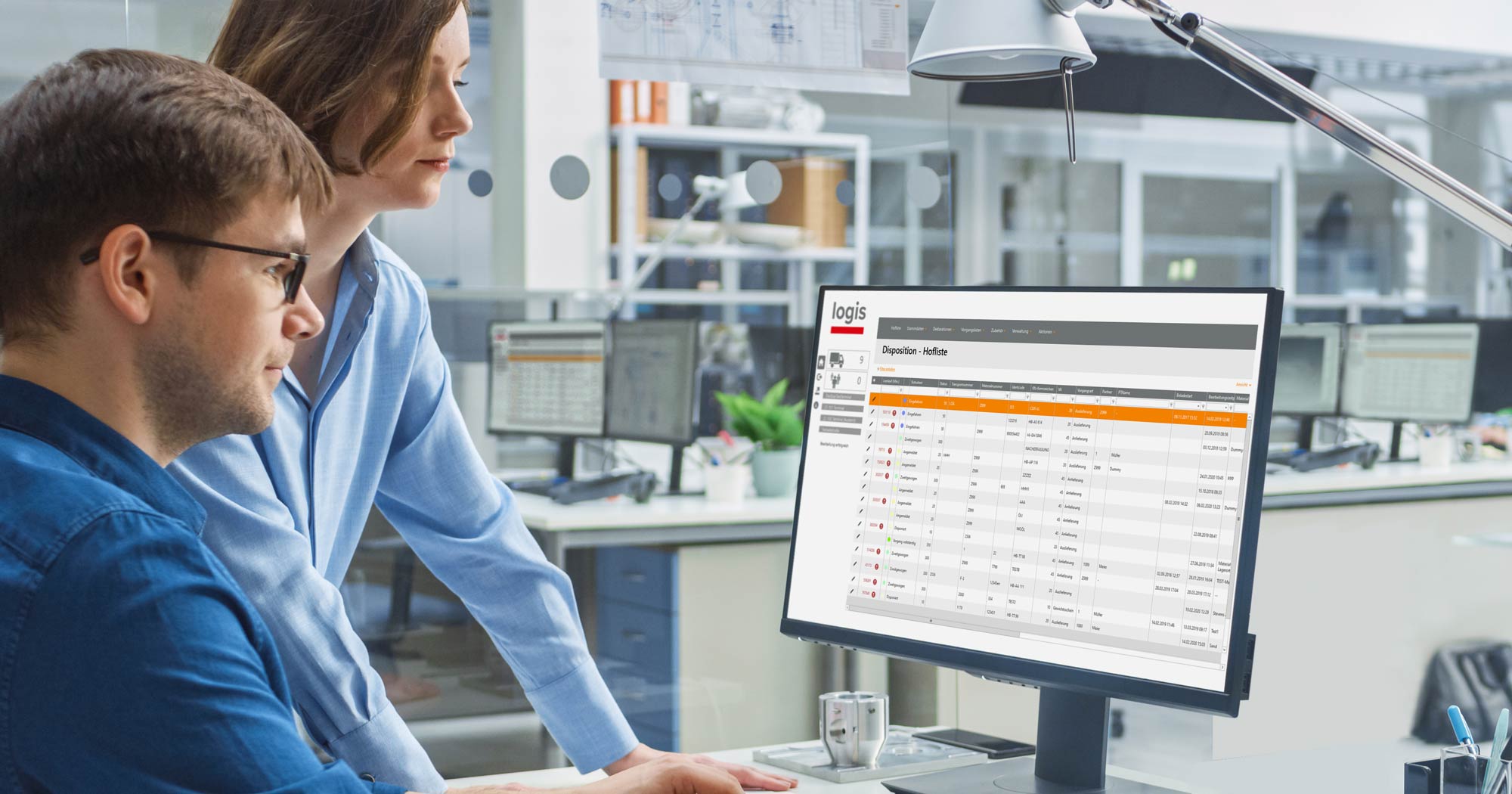

logis – automated yard management

The software designed to control logistic processes

Our yard management software logis is the perfect intralogistic supplement – from the plant access through to the plant exit. With logis, you keep perfect track of all lorries and goods transported on site.

In principle, all business areas, e.g. warehouse, site security, scheduling, and IT, are integrated in the yard management sequences. However, logis is composed of several modules, which you can combine as required in your company – in this way our yard management software guarantees a perfect and flexible use of the resources available.

The software for yard management complements our yard automation hardware solutions featuring the logistic terminals and traffic routing systems.

Our yard management software solution provides for:

- automatic handling of the logistic processes in transportation of material and goods

- attended weighing

- maximum transparency regarding the monitoring of door-to-door and waiting times

- high efficient processes, such as the provision of vehicles

- complete control and monitoring of the lorries all the time they are on site