Expansion of your silo plant

Often the required number of raw materials increases and an increase of your silo and dosing capacities becomes necessary. In our modular silo system, all the components required for this, from dosing to compressed air generation, are compactly installed, so that self-sufficient operation is possible with the shortest conversion time. Only a receiving container is integrated into the existing plant. Depending on the design, height and side walls, your existing silo system can also be individually extended with our modules.

Due to the well thought-out concept, the silo system is also used for the construction of new row systems. If you are planning to build a production plant including a silo for bulk materials and raw materials in your company, you will remain flexible and prepared for all eventualities with our modular silo plant.

Get free advice now!

Construction of the silo plant

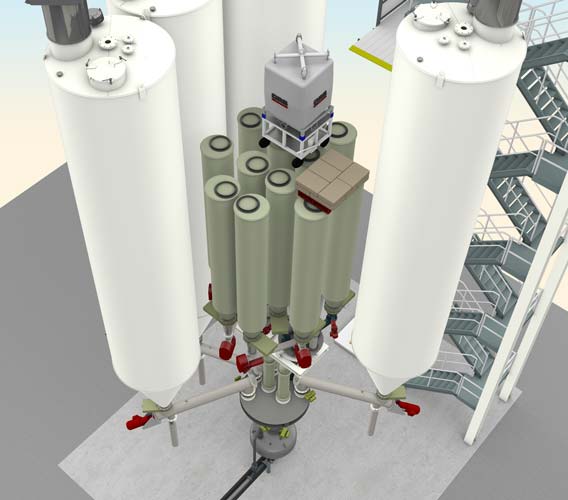

The expandable silo plant is constructed in a honeycomb shape on an area of just 10 x 12 m. The construction height varies depending on the silo type. Depending on the silo volume, the construction height is between 18 m (50 m³ silo volume) and 30 m (90 m³ silo volume). The basic equipment includes three silo chambers with round side walls made of high-quality steel or stainless steel. A large silo with a double chamber forms the centre of the plant, around which up to eight additional daughter silos can be built in a circular shape. The plant's expansions provide a quick and uncomplicated solution to additional raw material requirements and an increase in dosing capacity.

The dosing units, the weighing system, the raw material conveying station, the air compressor, the control system and the stairway to the roof of the round silo are located within the basic module of the modular silo system. The material is conveyed to the mixing plant via a pressure transmitter or, alternatively, via a bucket elevator. The receiving container in the mixing plant can either be a new container with a filter or, if there is not enough space, it is conveyed directly into an existing scale. The OAS process control system pronto takes over the uncomplicated control for your silo plant and the entire production.

Patented design with integrable small and medium component station

As an option, an integrated small and medium component station can be installed in the central mother silo. The patented solution comprises up to 12 integrated small and medium component silos, which are filled via bagged goods and big bags. In addition to the large component scale, the mother silo also offers space for up to two further small and medium component scales,

which are designed for the required dosing accuracy. The required cycle time is maintained by means of a double batch offset. With this variant, all components can be fed into the mixing system via a single

pneumatic transmitter into the mixing unit. This saves time and energy.

Moderate investment

The modular concept of the silo module plant allows for a demand-oriented expansion stage. The minimised effort in terms of steel construction and cladding additionally reduces the costs compared to a conventional system design. This keeps the investment manageable and limited to your actual needs.