More efficient plant logistics with yard management by OAS

Targeted use of yard management to save resources

Yard management, plant logistics, and despatch automation respond to the cross-sectoral challenge: increasing the transparency and the efficiency of the entire flow of materials and goods. To this end, the time windows for delivery, supervision, and control of the delivery traffic at the receipt of goods is managed within the scope of the yard management. This includes the assignment of parking spaces in coordination with the operations required in the warehouse to take in and out of stock. The management of the gates (docks) and waiting areas for lorries (yard) plays a role, as well.

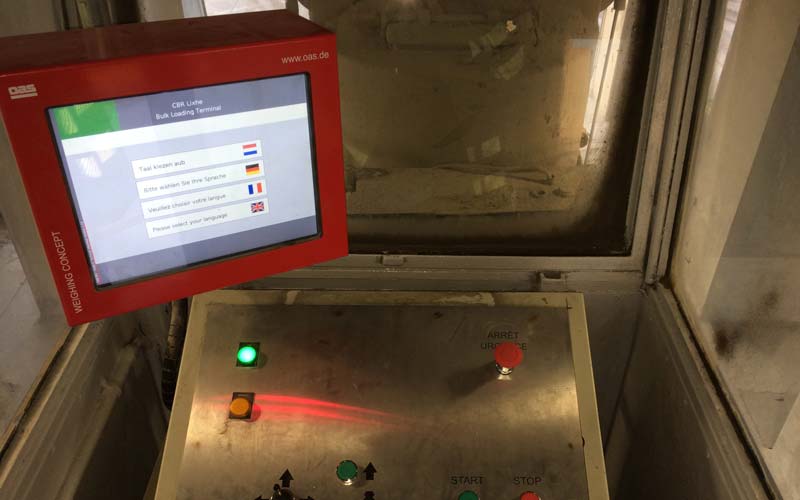

The costs resulting for yard automation always depend on the components selected. The corresponding hardware and software elements should in principle allow for branch-specific requirements. The costs are in contrast to vast savings – a result of the optimised plant-logistic processes and the saved resources going along with this. The hardware and software for yard management we are using are made at OAS to meet our quality standard. Moreover, our logistic terminals are designed for a long service life. Furthermore, the self-service terminals with their modular structure can be adapted to future tasks in a flexible manner. These features still increase the value of an investment in yard management components.

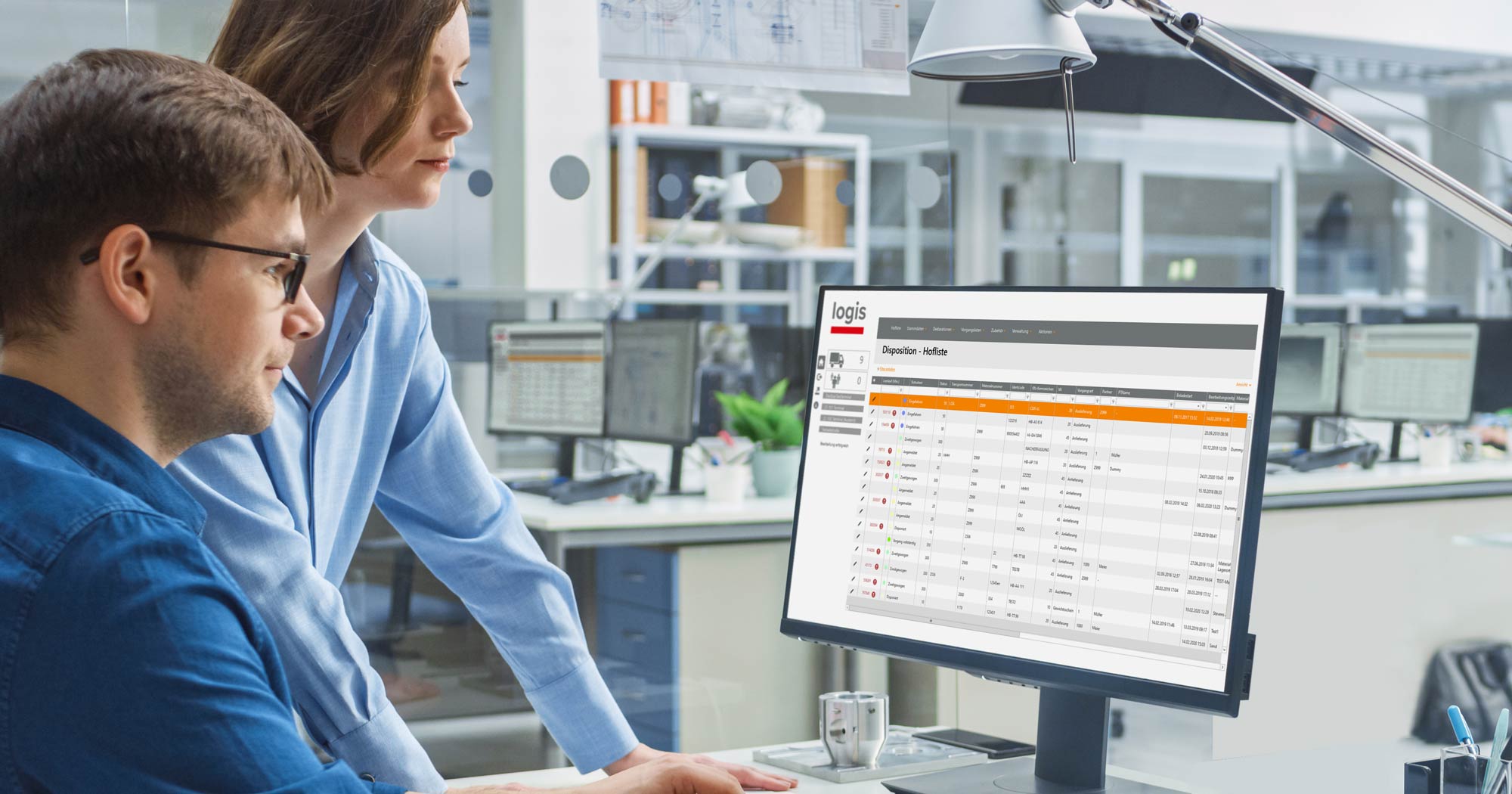

![[Translate to English:] logis yard management software](/fileadmin/_processed_/0/f/csm_logis-oas-header-2000x1050_0f7a64a71c.jpg)